In the logistics and transportation industry, selecting the right equipment for heavy loads is crucial for ensuring safety and efficiency. Among the various products available, the D Ring Truck Vinyl Tarp stands out as a vital component for securing and protecting cargo. According to a recent industry report by the Cargo Safety Institute, improper tarping can result in over 30% of load damage during transit, emphasizing the importance of choosing high-quality tarps that withstand harsh conditions.

Expert in cargo management, John Stevens, states, "A reliable D Ring Truck Vinyl Tarp not only offers durability but also ensures that your load remains secure throughout its journey." The D-ring feature allows for versatility in tie-down points, accommodating various load shapes and sizes, which significantly enhances the effectiveness of securing heavy cargo. Given the increasing demands in the transportation sector, understanding the specifications and benefits of D Ring Truck Vinyl Tarps becomes paramount for operators aiming to optimize their logistical operations and minimize risks associated with load security.

As we approach 2025, the advancements in materials and design will further redefine the standards for D Ring Truck Vinyl Tarps, making it essential for businesses to stay informed about the latest innovations in order to choose the best option tailored to their specific needs.

D Ring truck vinyl tarps play a crucial role in securing heavy loads during transportation. These tarps are designed with reinforced D rings that provide added strength and durability, making them ideal for use in trucking and hauling. The importance of using high-quality tarps cannot be overstated, as they not only protect cargo from environmental elements such as rain, wind, and sun but also prevent shifting and damage during transit.

When selecting a D Ring truck vinyl tarp for heavy loads, it is essential to consider factors such as material thickness, reinforcement design, and overall size. A thicker tarp made from premium vinyl ensures better resistance to wear and tear, while adequate size guarantees full coverage of the load. Additionally, the positioning of the D rings helps in securing the tarp firmly, reducing the likelihood of flapping or tearing during travel. By understanding these key features, users can make informed decisions that enhance load protection and transport efficiency.

| Feature | Description | Importance |

|---|---|---|

| Material Thickness | Typically 18oz to 24oz, durable against abrasion and tearing. | Higher thickness provides better protection for heavy loads. |

| D-Ring Reinforcements | Metal D-rings sewn into the tarp for secure tie-down. | Ensures the tarp stays in place and prevents slippage during transportation. |

| UV Resistance | Protection from harmful UV rays that can degrade material. | Increases the longevity of the tarp, making it cost-effective over time. |

| Waterproofing | Material designed to repel water and prevent leaks. | Essential for protecting cargo from rain and moisture. |

| Size Options | Available in various sizes to fit different truck loads. | Choosing the right size ensures complete coverage of the load. |

| Weight Capacity | Rated for specific weight limits, often up to 20,000 lbs. | Critical for safe transportation of heavy items without risk of damage. |

When selecting a D Ring truck vinyl tarp for heavy loads, several key features come into play to ensure that you are making the best choice for your transportation needs. First and foremost, consider the material quality and thickness of the tarp. Heavy-duty vinyl tarps typically offer superior durability and resistance to abrasions, tears, and harsh weather conditions. Look for a tarp that provides a high tensile strength, which is essential for securing heavy loads during transit.

Another crucial feature to evaluate is the D Ring spacing and construction. The placement of the D Rings should allow for even load distribution and secure tie-down options. Heavy-duty D Rings made from stainless steel or reinforced materials can enhance the tarp's overall strength and longevity. Furthermore, a tarp with reinforced corners and edges can provide additional support, preventing wear and tear that may occur with regular use. Pay close attention to these characteristics to ensure the tarp meets the demands of heavy hauling while maintaining integrity throughout its lifespan.

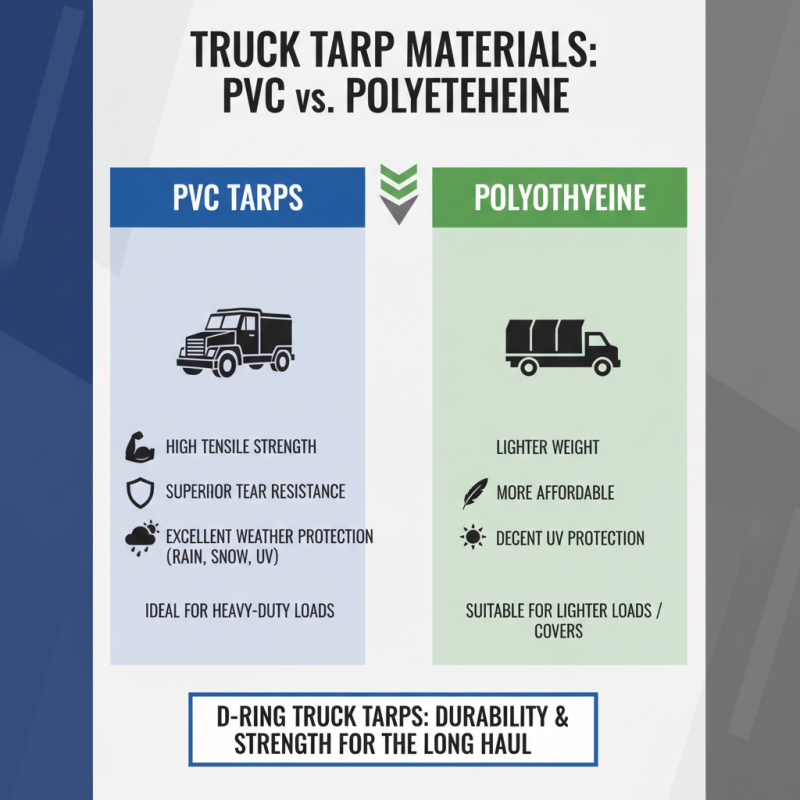

When selecting a D Ring truck vinyl tarp for heavy loads, the choice of material plays a pivotal role in ensuring durability and strength. The most commonly used types of vinyl for tarps are PVC and polyethylene. PVC, known for its high tensile strength and resistance to tearing, is often preferred for heavy-duty applications. Its ability to withstand harsh weather conditions makes it ideal for outdoor use, providing reliable protection against rain, snow, and UV rays.

On the other hand, polyethylene offers a lighter alternative that still maintains good durability and water resistance. While it may not have the same strength as PVC, its flexibility and ease of handling make it a popular choice for various hauling needs. Additionally, polyethylene is often less expensive, which can be an important factor for budget-conscious buyers. Ultimately, the decision between these two materials will depend on the specific requirements of the load being transported and the environmental conditions it will face during transit. Assessing the intended use and expected wear and tear can help in choosing the right vinyl that offers the best balance of strength and durability.

When selecting a D Ring truck vinyl tarp for heavy loads, assessing the size and fit is crucial to ensuring maximum efficiency and protection. The dimensions of the tarp should correspond closely to the size of the truck bed it will be used with. Measuring the truck bed length, width, and height is the first step; this will help prevent any gaps that could allow debris or rain to penetrate during transit. Additionally, consider the height of the loads being carried, as taller items may require a longer tarp to secure them adequately.

Another important consideration is the tarp's drop length. This is the excess material that extends beyond the edges of the truck bed, which allows for secure fastening. A drop length that is too short may result in the tarp not properly covering the cargo beneath, exposing it to the elements or making it more susceptible to damage during transport. Conversely, an excessively long tarp can be cumbersome and may create flapping that complicates driving conditions. Therefore, finding a balance in the tarp’s dimensions ensures that it fits snugly and securely around the load while also providing ample coverage for protection.

To ensure the longevity of D Ring truck vinyl tarps used for heavy loads, proper maintenance and care are essential. According to a report by the Industrial Fabrics Association International (IFAI), neglecting tarp maintenance can reduce their lifespan by up to 50%. Regular inspections are crucial; users should check for signs of wear and tear, such as fraying edges or punctures. When minor damage is detected, immediate repairs using high-quality adhesive patches or sewing can prevent further deterioration.

Another vital aspect of tarp care involves cleaning. The American Society for Testing and Materials (ASTM) recommends using a mild detergent and water solution to clean vinyl tarps regularly, especially after exposure to dirt and debris, which can degrade the material over time. It is also important to avoid harsh chemicals that may compromise the fabric's integrity. After cleaning, ensure the tarp is completely dry before folding or storing it to prevent mildew and mold growth, which can significantly weaken the material. Providing proper storage conditions, such as avoiding prolonged exposure to sunlight and extreme temperatures, can further enhance the longevity of the tarp, ensuring that it effectively meets heavy load requirements for years to come.